by Kai Staats

- Created: Tuesday, December 25 2018 00:53

Since our September update, we have seen the completion of the refurbishing of the telescope, packaging, crating, and shipment to Tanzania. While the photos alone tell the story, I offer a brief synopsis of our shared efforts …

Many thanks to Dan Heim for his steadfast attention to detail, application of every-day physics, and expert hand in modifying and fabricating new parts. It was for me a very special time to work side-by-side with the most influential teacher in my life. Together, we tackled a number of challenges, working to make something old as good as new.

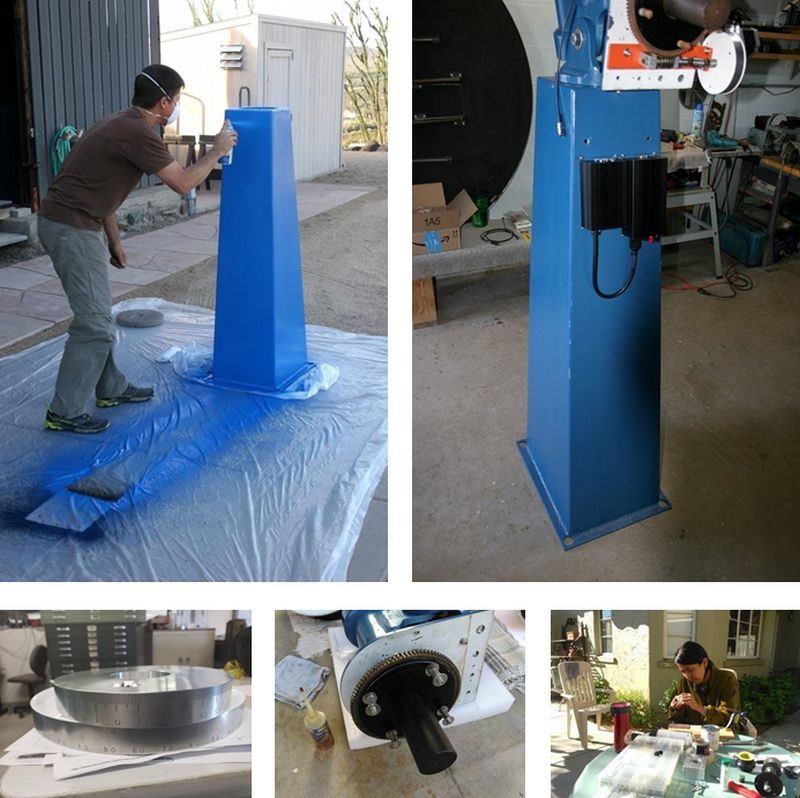

Alan Buckman of AWR Technology (www.awrtech.co.uk), Kent, England delivered the DC stepping motors, modified drive shaft, and programmed controller to correctly match the gear ratios in the declination and right acsension transmissions. Phil Sadler of Sadler Machine Co., Tempe, Arizona machined a mounting block for the new declination motor. Dan and I assembled the rebuilt transmissions, tested the motors both off- and on-chasis, and fitted the power supply assembly to the steel pedestal. Colleen Cooley gave her hand at tapping holes in the pedestal for cable restraints.

The primary and secondary mirror mounts have been fully rebuilt, with a new coat of black paint, stainless steel fasteners, and new cork and felt mounting points to securely hold the mirrors. The mirrors themselves were hand washed, rinsed with distilled water, and repackaged with new liners in their respective wooden crates.

Jeff Gehring of the Lowell Observatory (www.lowell.edu) machine shop completed the fabrication of a new declination setting circle, just 7” in diameter in place of the original 12”. Jeff’s work is in a word—beautiful. Thank you! This was required due to the new home for the telescope at three degrees south of the equator. There, the equatorial configuration will be nearly horizontal and the original, larger setting circle would strike the pedestal.

Every bolt, washer, and nut on the entire telescope, including the eyepiece mount has been replaced with stainless steel. The good folks at Walt’s Ace Hardware and Phoenix Bolt Company gave countless hours to this effort. Additional replacement parts are included in the shipment should one be lost or additional, on-site modifications be made.

The pedestal is sanded, primed, and repainted (having been scratched in the move from Wisconsin to Arizona earlier this year). A small can of matched touch-up paint is included in the crates, sand paper, epoxy, and brushes too.

I cannot thank my mother Linda Staats enough for her countless hours in research, phone calls, and email to locate the highest quality providers of crating and shipping. We are pleased to have engaged Dennis Davies of Craters & Freighters (www.CratersAndFreighters.com) and Darren Kayser of InXpress (www. inxpress.com) who donated his personal time to the path of least resistance from Phoenix, Arizona to Kilimanjaro, Tanzania, through myriad government regulations, customs, and fees. Thank you Colleen for your time and effort that saw 43 packages bubble wrapped for crating.

This brings to close another segment of this journey, started eight years ago by Chuck and Susan Ruehle, the Board of Directors of the Mt. Meru Astronomical Observatory, and the Racine Astronomy Club.

As of today, the 24th of December, the crates are in the hands of InXpress. Stay tuned—the best part is yet to come!

Cheers,

Kai Staats, MSc